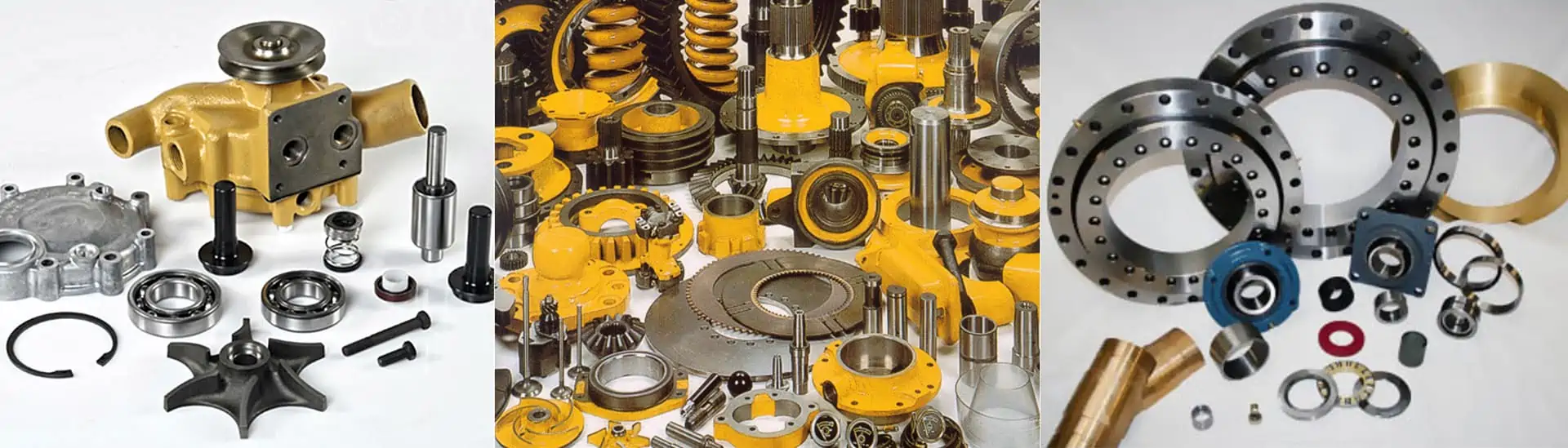

Enhance Your Heavy Equipment With Quality Aftermarket Building Components

Enhancing heavy machinery with top quality aftermarket construction parts can dramatically impact the performance and long life of your equipment. Whether you are wanting to enhance performance, resilience, or general capability, the decision to invest in aftermarket parts holds the capacity for significant advantages. From increased efficiency to economical remedies, aftermarket construction parts provide a variety of benefits that provide to the varied demands of hefty equipment drivers. By exploring the complexities of aftermarket parts, one can unlock a realm of possibilities for raising the efficiency of their equipment.

Advantages of Aftermarket Building And Construction Components

Enhancing hefty equipment with aftermarket construction parts can significantly boost efficiency and long life. Among the crucial benefits of utilizing aftermarket construction components is the possibility for improved resilience. Aftermarket parts are often designed with updated technologies and products, which can lead to machinery that can stand up to more strenuous operating conditions. This increased durability can bring about minimized downtime for maintenance and fixings, eventually improving total effectiveness and productivity.

Moreover, aftermarket construction parts can supply cost financial savings compared to buying initial equipment maker (OEM) components. While OEM parts are commonly much more costly due to brand acknowledgment and exclusivity, aftermarket alternatives offer an even more economical alternative without jeopardizing on top quality. This cost-effectiveness can be particularly beneficial for firms looking to optimize their functional expenditures without sacrificing the performance of their heavy machinery.

Factors to Think About When Choosing Components

When selecting building and construction parts for heavy equipment, it is crucial to carefully think about numerous factors to make sure optimum performance and compatibility. One important variable to consider is the quality of the components. Selecting high-quality aftermarket building components can dramatically impact the overall performance and durability of the equipment. It is necessary to choose parts from respectable suppliers known for their trustworthy and sturdy items.

An additional aspect to think about is compatibility. Making sure that the building parts are compatible with the details make and version of the equipment is important to avoid any functional problems or damage. This includes validating the measurements, specs, and any type of added demands for seamless integration.

In addition, thinking about the cost-effectiveness of the parts is essential. While top quality must not be jeopardized, selecting aftermarket components that provide a good equilibrium between top quality and expense can help in maximizing the worth of the investment.

Last but not least, accessibility and customer assistance should additionally be thought about. Decide for building parts that are easily available and backed by outstanding customer assistance to address any type of issues or questions quickly. By meticulously assessing these variables, you can make educated choices when choosing aftermarket building components for your heavy equipment.

Installation Tips for Aftermarket Parts

To ensure a smooth and reliable installation process for aftermarket building and construction components on heavy machinery, meticulous focus to information and adherence to maker guidelines are paramount. Prior to starting the setup, it is essential to thoroughly evaluate the aftermarket components to confirm that they match the specifications of the initial parts and are without any kind of flaws. Additionally, arranging the workspace and making certain that the needed website here tools are conveniently available can help simplify the setup procedure.

Complying with the manufacturer's installment directions is essential to assure proper fit and capability of the aftermarket parts. Any kind of variance from these standards might result in below average performance or perhaps potential security hazards. It is likewise advisable to record the installation process, consisting of any changes made or challenges came across, for future reference.

Finally, performing a final assessment after the installation is total can aid identify any kind of issues or errors that might have been overlooked - aftermarket construction parts. Checking the machinery to guarantee that the aftermarket components are functioning properly is a crucial final action in the installment process

Upkeep Standards for Upgraded Machinery

For optimum performance and longevity of updated equipment, adherence to specific upkeep standards is important. Regularly arranged upkeep checks are vital to make sure that all aftermarket components are operating correctly. This includes evaluating parts for like it wear and tear, lubricating moving components, and changing filters as required. Adhering to the manufacturer's recommended maintenance schedule is extremely suggested to avoid pricey fixings and unexpected breakdowns.

Along with regular maintenance, operators need to additionally focus on any type of unusual audios, resonances, or performance issues that might emerge. Attending to these problems quickly can prevent further damages to the machinery and its aftermarket parts. Maintaining in-depth records of maintenance tasks, repairs, and component substitutes can assist track the overall health of my website the updated machinery and recognize any type of repeating issues.

In addition, appropriate storage space and cleansing procedures must be followed to shield the machinery from ecological aspects that could increase endure aftermarket components (aftermarket construction parts). By complying with these upkeep guidelines diligently, drivers can make best use of the benefits of their updated machinery and guarantee its continued dependability on the job website

Cost-Effective Upgrades for Hefty Machinery

Carrying out strategic upgrades can considerably improve the efficiency and performance of hefty equipment while maintaining cost-effectiveness. When considering affordable upgrades for heavy machinery, it is necessary to focus on improvements that supply the most substantial impact on productivity without breaking the budget.

Another affordable upgrade is the combination of GPS innovation, which can enhance path planning, increase fuel efficiency, and improve overall job website performance. Updating to even more long lasting tires or tracks can likewise be a smart investment, as they can improve traction, reduce wear and tear, and ultimately expand the life-span of the equipment. Furthermore, retrofitting older machinery with energy-efficient components, such as LED lights or improved hydraulic systems, can bring about lasting expense savings through lowered power usage and maintenance expenses. By carefully picking and carrying out these affordable upgrades, heavy equipment drivers can take full advantage of performance and performance while remaining within budget constraints.

Final Thought

In final thought, aftermarket building and construction components use many benefits for improving hefty equipment. Generally, cost-effective upgrades with aftermarket parts can lead to boosted performance and performance in construction operations.

Enhancing heavy machinery with high quality aftermarket building components can dramatically influence the efficiency and long life of your equipment.Enhancing hefty equipment with aftermarket construction parts can significantly improve performance and longevity.Furthermore, aftermarket construction parts can offer cost savings contrasted to acquiring initial tools supplier (OEM) components.To make sure a effective and seamless installation process for aftermarket building and construction components on hefty machinery, precise attention to detail and adherence to manufacturer standards are vital. Prior to beginning the installation, it is crucial to thoroughly evaluate the aftermarket components to verify that they match the specifications of the original components and are complimentary from any type of defects.

Comments on “Unlock Efficiency: Aftermarket Construction Parts Choice Guide”